Digital technologies have a strong presence in Operators’ technology plans, with 23 out of the 55 Operators reporting technology targets in this category. This is also a trend that has seen constant growth since Technology Insights publication began.

Digital solutions are integral enablers of other technology areas across the life-cycle of oil and gas assets.

Cloud data management and advanced analytics (including machine learning) have been successfully introduced to better exploit existing reserves. “Connected Worker” technologies enable on-site crews to exchange technical and inspection data in real-time in the field via mobile networks using ATEX rated tablets and head-up displays.

Remote and non-intrusive inspection data are critical for successful asset management strategies such as in predictive maintenance.

Digital & Data technologies

Digital & Data applications are one of the strongest areas of interest according to Operators’ technology plans, with over 380 technologies submitted

Parallel to that, there is broad industry participation, with 23 Operators (42% of total respondents) having reported interest in digital technologies

Digital & Data is defined in this document as a ‘cross-cutting’ category, in which digital and data management are integral part of technology solutions in most areas of the offshore asset lifecycle.

Digital & Data technologies by area of application

Over 30% of Digital and Data technologies in Operators’ plans are very recent or still under development, suggesting that this is a more established area of UKCS technologies

Whilst the majority of technologies are provided and deployed by vendors and suppliers, in circa 23% of cases Operators take an active role in the development or customisation of the solutions for their assets’ needs

Readiness definitions: Early Development (TRL 1-4), Late Development/Pilot (TRL 5-7), Early commercialisation (TRL 8), Proven (TRL 9)

Operators are increasingly adopting “connected worker” technologies to enable on-site workers to communicate receive and record data in the field via mobile networks using ATEX rated tablets and head-up displays. Onshore and offshore control rooms enable remote operations and reduce offshore manning. New this year are digital instrumentation of Christmas trees and flowlines, safety critical maintenance via mobile app, and virtual reality Major Accident Hazard training in the field.

- Connected Worker - Digitalisation of Inspection and Anomaly Management - Use of remote connected technology linked to maintenance management system and previous surveys to reduce workload of offshore inspectors and maintenance teams

- TRL 9 Proven Technologies

|

Technology Example: By enabling workers at offshore sites to request over-the shoulder subject matter expert (SME) support from onshore personnel, a solution with this capability can become vital when a piece of equipment, critical to production, shows signs of fault or breaks down, due to the need to collect photographic evidence, send emails and organize conference calls between offshore engineers and SMEs |

|

- Onshore/Offshore Control Room linkage (Onshore Smart Rooms) - Set up onshore Operations Rooms where key onshore asset support staff can provide direct and timely support to offshore operations

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- SAP safety critical maintenance - mobile working - Introduction of SAP work management mobility solution delivering work order update and close out, creation of notifications, along with requests for master data updates.

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- 4G installation - Creating a network offshore to enable mobile working and more telemetry to be streamed onshore, 4G LTE to be implemented

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Well & Flowline Connectivity - Complete re-instrumentation of well Christmas trees and flowlines to allow reliable, remote visibility of valve positions, pressures and temperatures and better shutdown functionality.

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Virtual Reality MAH Awareness Training - The use of Virtual Reality training allows remote training of all different cases. In this case, it is being used for MAH awareness for all offshore personnel both new and refreshers on all Harbour assets. The main aspect of the VR training are: - Jet Fires, - Pool Fires, - Explosions

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Arnlea Intrinsix Introduction of mobile Arnlea Intrinsix app for EX-maintenance

- TRL 9 Proven Technologies

Innovations include improved methods of seismic data acquisition to increase resolution and improve reservoir sweep and laser scanning of assets creating 3D point cloud data with high accuracy, software extracting data directly from documents ensuring revision history is maintained, and digital well-books storing data and workflows to determine well potential. New this year are TAR management tools and flow surveillance using spectral logging technology. Emerging technologies include are through tubing CBL, casing wear logging and in-well monitoring in advanced/intelligent wells.

- TAR Management Tools - Automate scope gathering to improve accuracy of TAR and pit stop preparation. Manumatic reporting of TAR and Pit stop Execution - including associated inaccurate about projected end dates

- TRL 9 Proven Technologies

- Spectral Noise Logging for flow surveillance - Adopt Spectral Noise Logging Tool for reservoir flow surveillance. Results from 1st application (Jan 2019) were encouraging, further applications to evaluate benefit of the technology planned.

- TRL 9 Proven Technologies

- Ultra high density ocean bottom seismic (UHDOBN) - The acquisition of densely sampled seismic data to improve reservoir imaging.

- TRL 9 Proven Technologies

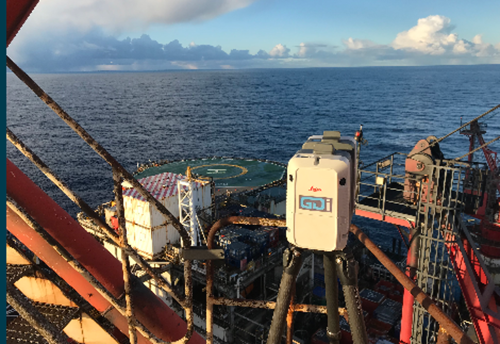

- Laser Scanning - Accurate construction data provided by laser imaging scanner to create 3D point cloud with greater than one mm accuracy

- TRL 9 Proven Technologies

- Well Activity Reporting Portal (WARP) - Digital Well Activity Reporting Portal - to improve drilling efficiencies and working practices

- TRL 9 Proven Technologies

- Digital WellBook - Integration in one single tool of all well information and workflows to determine well potential, compare performance against forecast, register and rank opportunities for improvement.

- TRL 5-7 Late Development/Pilot

- Probe / Archer through tubing CBL and casing wear logging - Through tubing Cement Bond Log and Casing wear analysis / modelling. This could be rolled out as part of drill preps to highlight any concerns on the 9 5/8" casing and also help plan for 9 5/8" cut depths for ANA and NSI wells. Could also use the CBL data to build database for future abandonment campaign.

- TRL 1-4 Early Development

- GDI Vision - Automating remote visual inspection. - Reducing offshore POB, reduced time to complete visual inspection, increased data quality and reduced human exposure. NZTC approved stage 2 of the GDI Remote visual inspection project - to fully automate inspection by utilising point cloud data.

- TRL 1-4 Early Development

|

Technology Example: GDi Vision provides clients with access to a web-based visual platform. This innovative web-based tool enhances operational and engineering functionality whilst delivering material cost benefits to our clients. |

|

- In-Well Monitoring in Advanced/ Intelligent Wells - Collaboration with the Herriot Watt Uni for development of tools and techniques for better use of distributed temperature system data with transient temperature and pressure analysis to aid reservoir and well management.

- TRL 1-4 Early development

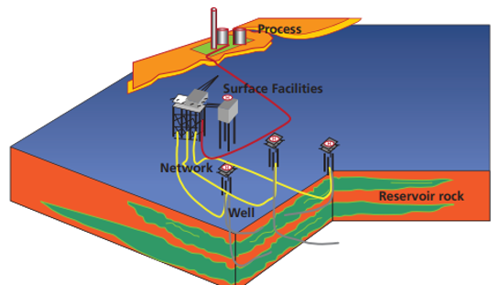

Operators report digital and database management systems for wells and subsea, software for operations management improvement, online lean check-in applications, and asset integrity management databases. New this year are operations management systems that integrate multiple business systems into one. Emerging this year is a flexible flowline integrity assurance methodology.

- Enhanced predictive maintenance for Drilling - The utilisation of digital data for enhanced predictive maintenance in drilling rigs

- TRL 9 Proven Technologies

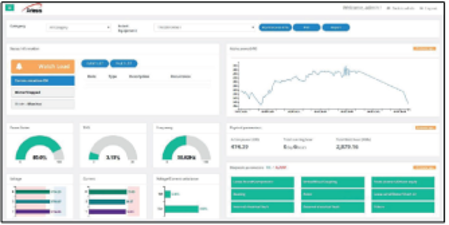

- Digital - Integrated Operations - Multiple technology deployments under Digital program comprising Integrated Operations Centres, IoT, Mobility and Data and Analytics streams to improve efficiency and effectiveness of offshore operations

-

TRL 9 Proven Technologies

-

|

Technology Example: Artesis e-MCM monitors your rotating equipment continuously, constantly taking measurements and comparing them with the digital twin it created during the self-learning process. Unlike conventional online systems, its unique machine learning algorithm allows it to recognise normal operation in a wide range of conditions, such as different speeds or loads |

|

- Asset Data Management Improvement and Digitization - Data Analysis\Mining\Cleanse\Metadata & Classification\Data Presentation & transfer from Documentum to SharePoint. Leidos & Evoke

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Operations Management Systems Improvement - During 2020 the Maximo Enhancement programme commenced which included the goals of improving Maximo integration with other sources of business data and managing software obsolescence. This includes a version upgrade and a longer-term goal of adding the Oil and Gas Bolt on.

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- BIS system - Consolidation of multiple business systems into a single data management system. BIS system

- TRL 8 Early Commercialisation

- Asset Integrity Management Database - Offshore/Onshore electronic manipulation of inspection data - ONE Database upgraded functionality

- TRL 5-7 Late Development/Pilot

- MyVantage Online App - "LEAN Checkin E2E process resulting a reduction in check in time. - LEAN process for cascading flight and safety information to Passengers. Allows passengers access to their personal details, training competencies, trip history and to receive electronic messaging on flight details

- TRL5-7 Late Development/Pilot

- Flexible Integrity Assurance - Developing the methodology with vendor (4subsea) to develop a standard fitness for service methodology for flexible pipes.

- TRL 1-4 Early Development

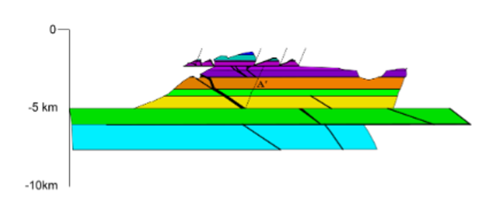

This sub-category includes advanced timelapse 4D seismic data processing techniques, subsurface modelling to better exploit existing reserves and locate missed pay opportunities, and adoption of AI/Machine Learning in subsurface modelling. New this year are novel processing methods including relative enhanced elastic impedance, and seismic volumes and depth dependant seismic facies inversion. Emerging technology includes subsurface modelling for CO2 storage.

- 4D Time-Lapse Seismic data processing - Acquire 4D time lapse monitor survey to image oil and water movements within the Forties reservoir. Primary tool used for locating infill drilling targets

- TRL 9 Proven Technologies

- Depth-dependent seismic facies inversion - Pre-stack simultaneous inversion using depth-dependent facies modelling

- TRL 9 Proven Technologies

- X-PAS Condition Monitoring & Services for Predictive Maintenance - OPEX Group's Condition Monitoring & Predictive Analytics Services are used for Predictive Maintenance on all 3 CNOOC UK assets.

- TRL 9 Proven Technologies

- IntrinsixEX - IntrinsixEX uses mobile Auto-ID technology such as RFID tags alongside strategies including RBI to increase compliance and decrease costs in your Ex inspections and maintenance activities.

- TRL 9 Proven Technologies

- Relative Enhanced Elastic Impedance (rEEI) - TGS have generated 'relative Enhanced Elastic Impedance' (rEEI) seismic volumes on reprocessed 3D to aid in hydrocarbon mapping, with relative intensity of response being indicative of pay thickness. The technique is does not rely on well conditioning and results are therefore independent of well data, meaning that well data can be used as an independent check on the predictions.

- TRL 8 Early Commercialisation

- Fullwave inversion (JIP with Imperial College) - JIP for the development of tools and techniques for improved seismic interpretation and processing with fullwave 3D seismic tomography and velocity model determination. Fullwave Gamechanger is an industry-academia collaboration with a research team at Imperial College, London. These are actively used in CNOOC.

- TRL 5-7 Late Development/Pilot

- AI/Machine Learning in Subsurface Modelling - application of learnings from ongoing collaboration with ENRGeo using Cygnus as an example.

- TRL 5-7 Late Development/Pilot

|

Technology Example: AI/Machine Learning in Subsurface Modelling - application of learnings from ongoing collaboration with ENRGeo |

|

- Gas Compression Analytics - Use of data science methods to improve gas compression up time

- TRL 5-7 Late Development/Pilot

- TRL 5-7 Late Development/Pilot

- Subsurface CO2 Storage Assessment - Subsurface modelling with potential for new data acquisition and processing to allow modelling of CO2 injectivity, migration within the reservoir and containment of the CO2 subsurface. Understand the risk from CO2 storage in depleted reservoirs and the critically the assurance of the containment within the reservoir and include the assessment and impact of P&A wells in the existing reservoir.

- TRL 1-4 Early Development

Operators report use of software driven solutions for production optimisation, decommissioning scheduling and plan optimisation, production loss analysis, and smart rooms linked to digital twins of offshore assets. New this year are real time well engineering, smart monitoring for ESPs, oncoming crew fatigue assessment apps and hydrocarbon accounting /production allocation software. Emerging this year is drill bit collision assessment software for areas of high well density/positional uncertainty.

- Real Time Well Engineering - Ensuring optimal drilling is accomplished maximises the productivity of drilling activities. Real-time drilling using latest AI technology

- TRL 9 Proven Technologies

- Improved Production Optimisation through use of GAP/RESOLVE – Operator currently has the Petroleum Experts (PETEX) Integrated Production Modelling software (IPM) composed of GAP, PROSPER, MBAL and PVTP which it utilises to optimise production in the field area.

- TRL 9 Proven Technologies

|

Technology Example: The concept of Integrated Production Modelling (IPM) was pioneered by Petroleum Experts and it involves the elimination of artificial boundary conditions. A change that is made on a pipeline model for example, will automatically change the behaviour of the wells and reservoirs upstream of that pipe, as well as behaviour of all the elements downstream. |

|

- EnergySys - Hydrocarbon accounting and production allocation system.

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Smart monitoring for ESP (Electrical Submersible Pumps) - Condition based monitoring and automatic optimisation of ESP (Electrical Submersible Pump) wells.

- TRL 9 Proven Technologies Fatigue Assessment App - Application for supervisors to assess the fatigue of new crew coming on shift. TRL 9 Proven Technologies

- Digital Oil Field System - Developed an integrated production system optimisation model to monitor well and field performance realtime and optimise production output using the PEtroleum Experts IFM/IVM/IPM tool set.

- TRL 5-7 Late Development/Pilot

- Digital Twin & Smart Room - Building a digital twin of Elgin Franklin to enhance efficiency and optimise working practices through a data centric approach

- TRL 5-7 Late Development/Pilot

- Reduce/eliminate risk of drilling collision issues caused by high well density and positional uncertainties plans - Complete technical and commercial review of At Bit Collision Detection development proposal. Failure to mitigate collision risk may reduce field ultimate recovery because some wells targets will be un-drillable or EOR injectors may be positioned sub optimally.

- TRL 5-7 Late Development/Pilot

Operators report use of technologies that enhance the ability to remotely monitor or inspect offshore assets, improve the assessment and tracking of anomalies, use of augmented reality from ROVs for subsea wellhead, tubing hanger, tree installation alignment, and subsea structure positioning New this year are integrity management software, thermographic camera surveys to detect passing valves and virtual reality platform walks for major accident hazard awareness training. Emerging technologies include hybrid digital twin technology for FPSO hull fatigue monitoring, metering monitoring software and inspection robots.

- Camera Surveys - passing valves - Thermographic setting on cameras will be used to indicate where valves on flare and vents may be passing. Existing technology but new use for it. (relevant to Bleo Holm Asset)

- TRL 9 Proven Technologies

- Xamin Integrity Management Software Development - Integration of water handling, pigging, anomaly management, PLUG reporting, annulus condition, integrity reporting and action tracking, all to support an efficient delivery of PIMS system

- TRL 9 Proven Technologies

- Anomaly assessment and tracking - The AA&T tool is a leap forward in how we manage our anomalies. It provides end-to-end traceability and reduces the amount of duplication in the current process. The cumulative risk profile will be far more visible, both in terms of local asset risk and a wider discipline view, which will hopefully drive continuous improvement to achieve safer and more reliable operations.

- TRL 9 Proven Technologies

- Virtual reality Kit - Virtual platform walks and also to be used for virtual reality major accident hazard awareness training

- TRL 9 Proven Technologies

- FUGRO Quickview - Quickview ROV augmented reality for Subsea wellhead, tubing hanger and tree installation alignment

- TRL 5-7 Late Development/Pilot

|

Technology Example: Fugro Quickvision involves a coded pattern which is stuck onto the subsea asset or foundation. The smart subsea camera is operated from an ROV. The smart camera combined with a range of sensors typically available on an ROV, tracks the coded pattern to measure the position, heading and attitude of the subsea asset in real time. |

|

- Hybrid digital twin technology for FPSO hull fatigue monitoring - Real-time digital hull integrity monitoring using strain gauges installed on the FPSO's hull

- TRL 5-7 Late Development/Pilot

- Ambrit - Improve accuracy of metering information onshore to improve condition monitoring and accuracy of metering data

- TRL 5-7 Late Development/Pilot

- Inspection Robot - Develop an automomous fabric maintenance robotic solution, utilising latest AI, machine vision and machine learning.

- TRL 1-4 Early Development