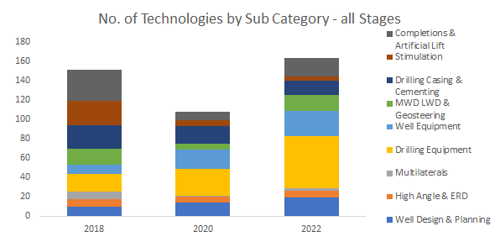

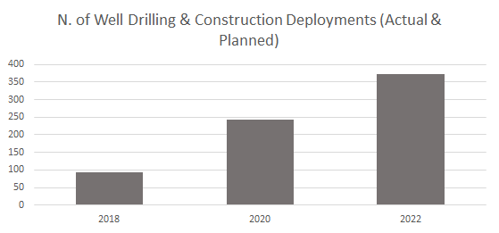

Well Drilling & Construction technologies have gained far more widespread use on UKCS in the past 4-5 years, Greater numbers of well surveillance and intervention technologies are being adopted by operators on multiple assets, improving knowledge of ongoing well status and monitoring of integrity issues, and reducing costs of interventions and dependence on costly rig based workovers.

Summary Findings (Click on Sub-Categories for detail)

- Well Design & Planning

Growth in digital well planning using and adopting AI is reported by a larger range of operators this year, specific design aspects and technologies for CO2 storage wells are on the increase - High-angle and ERD

Big bore wells and slimhole well designs are both being utilised for specific types of ERD, emerging technologies for digital solutions for drilling controls, and technologies for high accuracy surveying while drilling - Multilaterals

Multilateral Technologies to enhance production and alleviate slot constraints by accessing multiple zones or span out in different directions within a single reservoir. - Drilling Equipment/Well Equipment

Improving well access for interventions, managed pressure drilling technologies and low cost platform workover rigs/modular drilling rig systems - MWD, LWD & Geosteering

Operators are using deployable technologies such as digital software using Machine learning and AI for looking ahead of the bit during Geosteering, and logging while drilling, also deployable and emerging technologies for HFTO (High Frequency Tortional Oscillation) dampening - Drilling, casing and cementing

Deployable technologies include wireline deployed high pulse tool for scale removal and production stimulation, and hydraulic fracturing techniques to develop poor reservoir quality. - Stimulation

Deployable technologies include wireline deployed high pulse tool for scale removal and production stimulation, and hydraulic fracturing techniques to develop poor reservoir quality. - Completions & Artificial Lift

Operators technology plans for 2022 show adoption of multi function wireline tool-strings, and Intelligent completions and in emerging technologies we see H2S and hydrocarbon sampling in HPHT environments with SLB’s Ora system

Well Drilling & Construction technologies

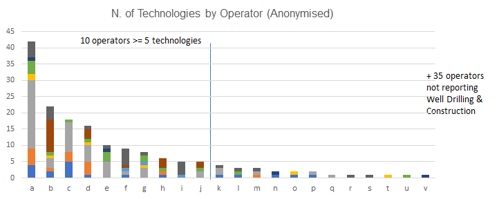

- Over 50 technology plans submitted each year from 2018-22

- Steady increase in number of technologies, with operators reporting interest in this area (Participation growing from 4 operators in 2018 to 22 operators in 2022)

- A number (35) of respondents not yet considering this theme (based on submissions)

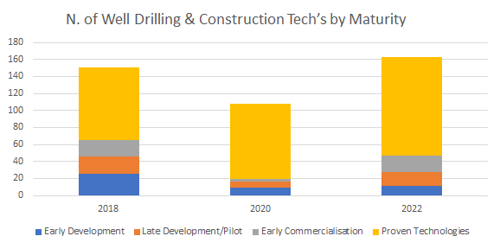

- Operators are focusing on a number of available technologies ready for deployment (Early Commercialisation (TRL 8) and Proven Technologies - Existing or in widespread use (TRL 9)

- The pipeline of technologies under development (TRL 1-7) remains healthy

Maturity and deployments

Once familiar with the technology the same operator deploys it at multiple assets (over 300 deployments reported/planned for 2021-23)

1. Well Design & Planning

In this sub-category the growth in digital well planning by using and adopting AI, is reported by a larger range of operators this year, specific design aspects and technologies for CO2 storage wells are on the increase as well

- Digital Well Planning - DrillPlan is a digital well construction planning solution that will allow you to maximize the results from your teams by giving them access to all the data and science they need in a single, common system.

- Equinor (Mariner), Harbour (Brittania) TRL 9 Proven Technologies

Technology Example :

SLB DrillPlan SoftwareDrillPlan* coherent well construction planning solution gives your well planning teams access to all the data and science in a single, common system. It provides the platform for a radical new way of working that gives you quicker and better-quality drilling programs by automating repetitive tasks and validation workflows to ensure your entire plan is coherent

View Technology

- Well Activity Reporting Portal (WARP) - Digital Well Activity Reporting Portal - to improve drilling efficiencies and working practices

- TotalEnergies (Culzean) TRL 9 Proven Technologies

- Well planning using artificial intelligence - Work with external provider to develop AI well planning too. Fast turnaround alternative well path trajectory screening.

- Ithaca (Captain) TRL 8 Early Commercialisation

- Reduce/eliminate risk of drilling collision issues caused by high well density and positional uncertainties

- Ithaca (Captain) TRL 5-7 Late Development/Pilot

2. High Angle & ERD

Big bore wells and slimhole well designs are both being utilised for specific types of ERD, emerging technologies for digital solutions for drilling controls, and technologies for high accuracy surveying while drilling.

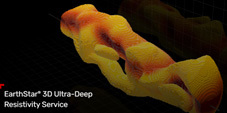

- EarthStar Ultra-Deep Resistivity Service - Advanced geosteering resistivity tool to place wells more accurately in the reservoir.

- Harbour (Brodgar)

Technology Example :

The EarthStar ultra-deep resistivity service is an innovative logging-while-drilling (LWD) technology that illuminates the reservoir by revealing reservoir formations and fluid boundaries up to 225 feet (68 meters) around the wellbore. It enables operators to position production boreholes accurately while mapping large volumes of the reservoir.

View Technology

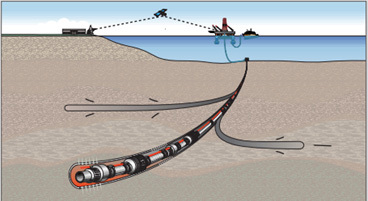

- Extended Reach Drilling (ERD) – with slim hole design - slim hole design be stimulated by hydraulic fracturing.subsea

- Ineos (Breagh)

- Ineos (Breagh)

Technology Example :

Improve ROP by safely maximizing drilling parameters

The OptiDrill service provides information for the rigsite team to identify the optimal drilling parameters to improve ROP. Simultaneously, the remote experts focus on the interpretation of longer-term trends, identifying performance limiters and anticipating risks. They also share opportunities for process improvement.

- Schlumberger DD Tools – High accuracy surveying to reduce error ellipses in ERD wells. Dual inclination and other survey tool combinations to reduce vertical and lateral error ellipses

- Harbour Energy (Brittania) TRL 8 Early Commercialisation

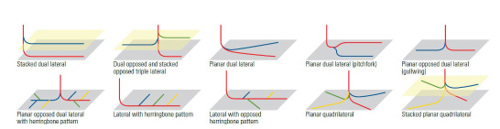

3. Multilaterals

Multilateral Technologies are a smaller sub-category with only 1 deployable and 2 emerging Technologies to enhance production and alleviate slot constraints by accessing multiple zones or span out in different directions within a single reservoir.

- Multi-lateral technology (MLT) - Enhanced slot recovery and use of non-conventional well technology to bypass slot restrictions. Multi-lateral technology to alleviate the slot constraints on the Magnus platform

- EnQuest (Magnus) TRL 9 Proven Technologies

- EnQuest (Magnus) TRL 9 Proven Technologies

Technology Example :

(Extract from SLB industry article “the defining Series – Multilateral wells)

The geometry of an ML well is determined by the production targets, their relative depths and lateral extents. The laterals may be on the same horizontal plane at the same true vertical depth or they may be on the same vertical plane and follow the same direction but at different depths. Within these two main categories, a nearly infinite number of combinations can be created that may cover multiple zones or span out in various directions within a single reservoir

- Multilateral Whipstocks - Continued research and development into improving whipstock system with focus on junction cement and design of plugs for mother bore.

- CNR International (Lyell, Ninian, Thelma, Toni) TRL 6-7 late Development Pilot

- Retrofit Multilateral Technology (RMLT) - Multilateral technology to allow for production from motherbore

- Spirit (Statfjord) TRL 1-3 Early Development

4. Drilling Equipment/Well Equipment

Drilling Equipment/Well equipment sub-category continues to show high quality solutions for improving well access for interventions, managed pressure drilling technologies and low cost platform workover rigs/modular drilling rig systems.

- Use of MPD - Use of active MPD with statically balanced and statically under balanced drilling fluids in HPHT environment

- Neptune (Seagull), Wintershall (Sillimanite), Harbour Energy (Tolmount) TotalEnergies (Elgin, Franklin) TRL 9 Proven Technologies

- Neptune (Seagull), Wintershall (Sillimanite), Harbour Energy (Tolmount) TotalEnergies (Elgin, Franklin) TRL 9 Proven Technologies

- StarSteer - Geosteering software that assists realtime geosteering decision during drilling by matching LWD log response against offset wells or models.

- Shell (Arran) ) TRL 9 Proven Technologies

Technology Example :

The new 90’ LynxTM Wire Line Mast is setting a new industry standard. Introducing superior efficiency, increased working environment and without the need for external cranes once installed. Also features BOP access in compliance with Norsok S-002,.

View Technology

- A number of low cost platform retrofittable workover rigs are being adopted such as Dwellop’s Lynx Mast and Wellvene’s WellHop lightweight wireline system, and Streicher modular drilling rig systems

- Harbour (Millom), Shell (Shearwater) ) TRL 9 Proven Technologies

- Harbour (Millom), Shell (Shearwater) ) TRL 9 Proven Technologies

- APTARA Christmas Tree - lightweight compact tree - Lightweight compact tree that removes complexity. The tree follows a modular design to reduce tree cost and lead times

- Siccar Point Energy (Cambo) TRL 8 Early Commercialisation

Technology Example :

The Aptara lightweight compact tree uses unique, patented tree caps that allow the tree to be configured to suit changing requirements—reducing cost and increasing value over the life of your field.

View Technology

- Streicher Continuous Circulating System - Streicher Continuous Circulating System (when tripping drill pipe) Enables lower mud weights to be used when drilling depleted reservoirs. Gives the ability to maintain ECD when making or breaking connections

- Harbour Energy (J-Block, Fleming, Talbot) TRL 6-7 Late Development/Pilot

5. MWD, LWD & Geosteering

LWD, MWD & Geosteering – operators are using deployable technologies such as digital software using Machine learning and AI for looking ahead of the bit during Geosteering, and logging while drilling, also deployable and emerging technologies for HFTO (High Frequency Tortional Oscillation) dampening

- Schlumberger Geosphere - Geosteering in thin reservoir intervals using LWD resistivity imaging technology to look ahead of the bit through inversion.

- Harbour Energy ( Jade, Jasmine, Judy & Joanne), CNR International (Columba B/D), Neptune (Cygnus) TRL 9 Proven Technologies

- Harbour Energy ( Jade, Jasmine, Judy & Joanne), CNR International (Columba B/D), Neptune (Cygnus) TRL 9 Proven Technologies

- Pickasso - Machine learning for autotracking seismic horizons and faults, Geosteering Software

- Shell (Gannets & Pierce) TRL 9 Proven Technologies

- Shell (Gannets & Pierce) TRL 9 Proven Technologies

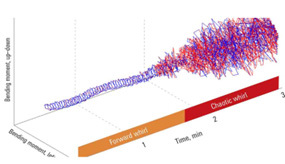

- CoPilot3 - In combination with HFTO dampener tool, CoPilot3 used to control torque applied at bit thus ensuring HFTO dampener tool operates within limits, but also optimizes downhole WOB, which appeared to improve ROP on first application compared to a direct offset well.

- Apache (Beryl TRL 9 Proven Technologies

- Apache (Beryl TRL 9 Proven Technologies

Technology Example :

The CoPilot™ ultra-high-definition (UHD) service measures downhole drilling dynamics in real-time and records ultra-high-definition data to memory during dysfunctional drilling events

View Technology

- Logging Whilst Drilling (LWD) - Ultra-deep azimuthal resistivity for deep reading sand architecture evaluation and geo-steering.

- TotalEnergies (Ballindalloch) TRL 9 Proven Technologies

- TotalEnergies (Ballindalloch) TRL 9 Proven Technologies

- TVI sub - to mitigate against HFTO TVI sub to mitigate against HFTO - TVI sub to mitigate against High Frequency Torsional Oscillation (HFTO)

- Apache (Beryl) TRL 8 Early Commercialisation

- In 2022 Technology Survey Data there are no Emerging Technologies in this sub-category

6. Drilling Casing & Cementing

A range of deployable technologies for Drilling, Casing & Cementing – high temperature drilling muds, downhole drill parameter monitoring, swellable sleeves to reduce risk of SCP (Sustained Casing Pressure) with emerging technologies of new casing design to improve cement bond quality

- Perf & Wash cement placement - Perf & Wash cement placement provides a lateral isolation across two separate isolation intervals

- TotalEnergies (Forvie North) TRL 9 Proven Technologies

- TotalEnergies (Forvie North) TRL 9 Proven Technologies

- Therma bore high temperature mud - Therma bore high temperature mud in the Bacchus reservoir.

- Apache (Forties) ) TRL 9 Proven Technologies

- Apache (Forties) ) TRL 9 Proven Technologies

Technology Example :

Pure-Bore® system has several advantages such as a highly shear thinning rheology, no bit balling, improved ROP, significant shale encapsulation, improved solids control efficiency through finer shaker screens hence reduced dilution volumes.

View Technology

- Purebore Rheology mud - For a thinner and tougher filter cake, Pure-Bore system has a highly shear thinning rheology, no bit balling, improved ROP, significant shale encapsulation, and improved solids control efficiency

- Apache (Forties) ) TRL 9 Proven Technologies

- Apache (Forties) ) TRL 9 Proven Technologies

- Swellable Sleeves - Prevent occurrence of future SCP / SCVF & safeguard ability to complete efficient EOW abandonment

- Shell (Gannet A) ) TRL 9 Proven Technologies

Technology Example :

Halliburton Swellpacker Zonal isolation systems are based on the swelling properties of rubber in hydrocarbons, water, or both. Additionally, self-healing properties allow Swellpacker systems to adapt to shifts in the formation over time, thus maintaining seal integrity.

View Technology

- CE-Bond (Centraflow) - - A new casing assembly which circumferentially enhances primary cement bond quality

- Apache (Forties) ) TRL 9 Proven Technologies

- Small Margin Drilling in Pressure Transition Zone - Accurate Measurement of casing setting depth in pressure transition zone above reservoir

- TotalEnergies (Culzean) TRL 5-7 Late Development/Pilot

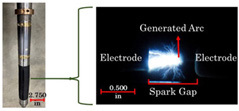

7. Stimulation

Stimulation sub-category is another of the smaller sections deployable technologies include Blue-Sparks WASP wireline deployed high pulse tool for scale removal and production stimulation, and hydraulic fracturing to develop poor reservoir quality

- Application of Hydraulic fracturing in Cygnus - 10th infill well is planning to drill a vertical, hydraulically fractured well to develop poor reservoir quality areas. This will be the first application of hydraulic fracturing in Cygnus.

- Neptune (Cygnus) TRL 9 Proven Technologies

- Neptune (Cygnus) TRL 9 Proven Technologies

- Cleansorb - ORCA chemical treatment for OBM filter cake removal 2 x Wells. Dual chemical attack with a single treatment for removal of Oil Based Mud Filter cake across reservoir, prior to completion. Hydrocarbon solubilisation treatment along with an in-situ acid generation to dissolve carbonate filter cake

- Apache (Beryl) TRL 9 Proven Technologies

- Apache (Beryl) TRL 9 Proven Technologies

Technology Example :

Bluespark WASP - Wireline deployed high pulse tool for scale removal and production stimulation (video)

View Technology

- Wireline deployed scale removal tool - BlueSpark WASP - Wireline deployed high pulse tool for scale removal and production stimulation. WASP tool has been used in a Buzzard well to remove potential plugging from stand alone screens.

- CNOOC (Buzzard), TAQA (Cormorant, Tern) TRL 9 Proven Technologies

- In 2022 Technology Survey Data there are no Emerging Technologies in this sub-category

8. Completions and Artificial Lift

Operators technology plans for 2022 show adoption of multi function wireline tool-strings, and Intelligent completions and in emerging technologies we see H2S and hydrocarbon sampling in HPHT environments with SLB’s Ora system

- Combined Wireline Toolstrings - "Single run toolstring to punch tubing and set straddle for use in retro-fit gas lift applications. Saving a toolstring run on LWIV operations. Bridge Plug with integrated Junk Catcher, again saving an additional wireline run."

- Shell (Brent, Pierce)

- Shell (Brent, Pierce)

- Intelligent well completion - Planning to deploy intelligent wells with intervan control valves and fibre optic pressure/temperature sensing over the reservoir in the upcoming infill wells.

- CNOOC (Golden Eagle)

- CNOOC (Golden Eagle)

- CO2 Injection Well Design - DHSV Design - Initial flow assurance results have indicated cryogenic injection conditions for the majority of the wells design life. Among the challenges associated with this is the impact of the cold temperatures on the ability of the DHSV (DownHole Safety Valve) to successfully close and seal the well when required.

- Harbour Energy (Victor)

- Autonomous Inflow Control Devices (AICDs) - ICDs are generally used in formations with varying permeability that are in compartmentalised layers across a deviated trajectory. They are normally of 'fixed' design that act as a pressure restrictor or 'choke' along the reservoir section and by doing so, assist in levelling out the inflow performance across the reservoir section to aid in full oil recovery before the onset of water.

- KNOC/Dana (Barra) TRL 8 Early Commercialisation

- Schlumberger Ora - H2S and hydrocarbon sampling in challenging well environments such as HP/HT to decide on completion design. Investigating Wireline high pressure / high-temperature sampling for H2S and fluids

- Harbour (Brittania, Lomond, Jade, Jasmine, Judy) TRL 8 early commercialisation

- Harbour (Brittania, Lomond, Jade, Jasmine, Judy) TRL 8 early commercialisation

Technology Example :

Ora intelligent wireline formation testing platform Revolutionizing dynamic reservoir characterization by combining new digital hardware with cloud-native collaborative software for unprecedented performance and insights in all conditions

View Technology

- In 2022 Technology Survey Data there are no Emerging Technologies in this sub-category